April 6, 2024

The induction heating equipment of copper ingot is the main equipment for heating copper bar and copper ingot forging. The electromagnetic induction heating principle is adopted to achieve rapid heating, which ensures the uniformity of heating temperature of copper bar, high efficiency, simple and convenient operation, energy saving and reliable operation. This equipment is equipped with automatic temperature measurement, temperature control and automatic feeding and discharging system, so that the induction heating of copper ingot forms an automatic production line, and is also an indispensable heating equipment for intelligent factories.

Technical requirements for copper ingot induction heating equipment

- heating specifications: medium 122x320, medium 122x400, medium 172x500, medium 172x420;

- heating temperature: 400-1200℃

- Temperature range after heating: temperature uniformity of single ingot +15℃, temperature uniformity of the same batch of ingot ±20℃:

- support continuous production function, can automatically adjust the temperature according to the setting, temperature closed-loop control:

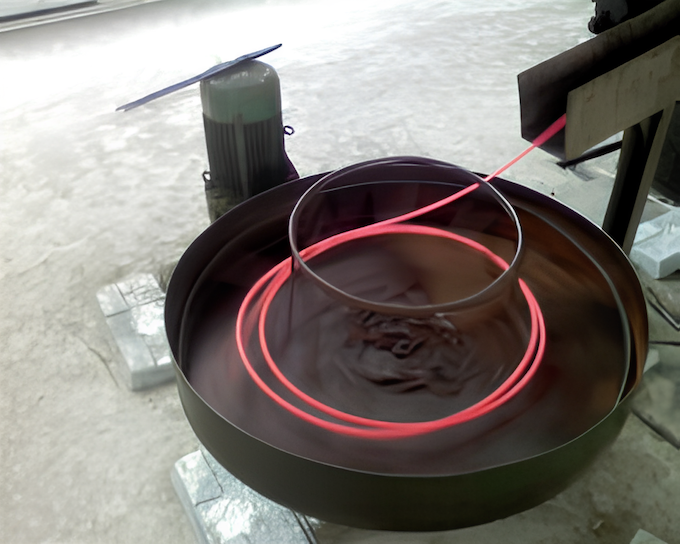

- heating using medium frequency furnace induction heating;

- Automatic feeding and discharging;

- support automatic/manual ingot, automatic ingot, the beat ≤2min/ piece, automatic ingot can be linked with the extrusion machine:

- support online temperature measurement.

copper ingot induction heating equipment features

- high efficiency and energy saving: induction heating method can directly convert electrical energy into heat energy, high thermal efficiency, energy conversion rate is much higher than the traditional heating method, thus saving energy.

- uniform heating: Because induction heating is directly acted on the inside of the copper ingot through the electromagnetic field, it can achieve uniform heating, avoiding the temperature uneven phenomenon that may occur in the traditional heating method.

- environmental protection and no pollution: there is no need to burn fuel in the induction heating process, so it will not produce harmful gases and smoke, in line with environmental protection requirements.

- easy to operate: copper ingot induction heating equipment is usually equipped with intelligent control system, can easily adjust the heating temperature, heating time and other parameters, to achieve automatic operation. The induction heating equipment of copper ingot is widely used in the fields of gold thermal processing, heating forging, etc. The use of this equipment can significantly improve production efficiency, reduce production costs, and also help to improve product quality.